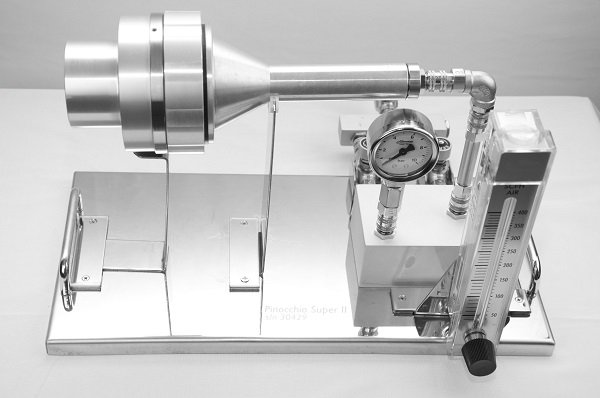

Instrument Air Validation

Validation activities can be applied to all aspects of the product in any of its intended environments such as operation, training, manufacturing , maintenance and support services. Vijaya Enviro Labs validate compressor air in all kinds of industries as the demand for compressed air quality depends on its usage and Vijaya Enviro Labs can also validate compressed air in some industries where they require extremely high quality air along with Breathing Air Validation, Instrument Air Validation and Nitrogen Gas Validation.

Instrument Air- The Quality of air is important to ensure that instrumentation will function properly and reliably.

The most important parameters in specifying air quality are:

- Dew Point

- Oil Content

- Particulate matter

- Moisture Content

- Viable Count.

The Instrument Society of America sets quality standards for instrument air in ISA S7.3.

Dew Point Dew Point - The Dew point temperature or Saturation temperature can be defines as the temperature at which condensation or moisture begins when moist air is cooled. This temperature can be determined by observing, either visually or by a photoelectric cell, condensation of water vapour on a polished metal surface that is slowly being chilled.

When an air-water vapour is compressed:

Its ability to hold water is decreased, Water vapour will start to condensate at a higher temperature and The dew point of the mixture at elevated pressure will be higher than that of the same mixture at atmospheric pressure.

The Dew point required for an instrument air system is generally set by the minimum ambient temperature to which the instrument air system will be exposed. The dew point at line pressure shall be at least 10oC (18oF) below the minimum local recorded ambient temperature. In cold climates, a -40oC dew point is typically used. In warmer climates the Dew Point temperature can be increased appropriately. Under no circumstances should the Dew Point at line pressure exceed 2oC (35oC). It is important that the Dew Point temperature be specified at the operating pressure of the instrument air system and not atmospheric pressure. This will ensure that no condensation of water will occur anywhere in the system.

Oil Content- Oil free air is generally required for an Instrument Air System. In an oil free system, an Oil content of less than 0.01 ppm is generally specified.

Particulate Matter- PM in the air may plug the small passages in some valves and Instruments. Instrument Air is generally filtered to remove Particulate Matter to a level less than 0.02 mg/m3 (size 100% <0.01 micron).

Temperature- When any gas is compressed its temperature will increase. For an Instrument Air System, this increase in temperature is undesirable. After coolers are generally provided immediately after the compressor to cool the air and remove the heat of compression. A typical outlet temperature is a maximum of 40oC..

Moisture- For an Instrument Air System, Moisture can cause rust in distribution pipes. It is important to dry the air prior to distribution to prevent problems in the system. It becomes troublesome when Oil and lubricants are combined with Moisture and Solid Contaminants to form a sludge that can clog instruments. Moisture content should be less than <0.01% for Instrument Air System.

Viable Count- For an Instrument Air System, Viable count should be (<100CFU.) Micro-organisms can be formed when there is any particulate matter or moisture forms in an instrument.